A Braking System is designed to control and halt the moving automobile vehicle, to pull off this, various components within the Brake system should convert the moving object from kinetic energy into heat energy, this conversation of force is carried by friction, which reduces the speed and also helps in de-accelerate the vehicle.

This Frictional force is generated by the Frictional contact of bodies between the shoe and the moving drum or disc of an automobile braking system.

Friction opposes the body that is in contact with each other by relative motion, so when you use energy to counter the friction it produces heat, and components such as pads, liners, drums, and discs get heated during the process and act to slow down the moving body.

The Frictional force depends upon the surface nature of materials, to achieve the braking effect of a moving body it depends on the speed of relative motion.

Hence to experience higher friction the bodies should be pressed comparatively more together, and also the faster the relative body moves in relation to each other lesser friction would be experienced between them.

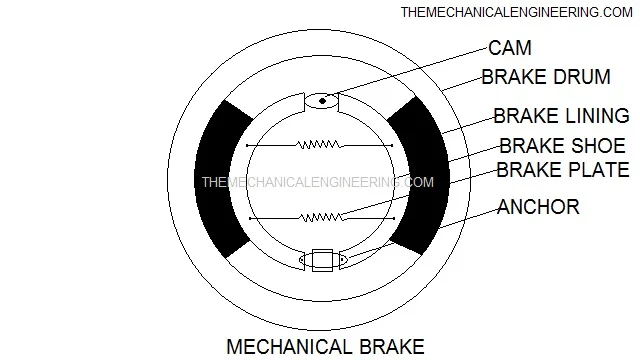

Design and Basics: The manufacturer placed two brake shoes in such a way that they collide against the inner surface of the Brake drum that resembles to form internal expanding brakes.

The drums surround the mechanism of brakes and form a layer to protect them from dust and moisture. The Backing plates grip the brake attached and complete the braking system attachment.

It acts as a catalyst for speeding up the brake shoe and its operating mechanism.

What are the different types of Brake or Braking Systems?

Most Brakes use friction on both sides of the wheel, the collective wheel pressing converts kinetic energy into heat energy.

For eg: (A regeneration braking system helps in the transformation of the energy into electrical energy, which also can be stored and used later. Eddy current brakes used magnetic fields to process kinetic energy into electrical current and The brake disc, which is then converted into heat).

It’s always good to know which of these braking systems fits your modern car’s needs for easy troubleshooting and servicing.

So let’s have a look at the different types of Braking systems:

- Mechanical Brake System

- Hydraulic Brake System

- Pneumatic Brake System

- Electromagnetic Brake System

- Servo Brake System

- Electrical brake system

- Disc Brake System

- Drum Brake System

- Emergency Brake

- Anti-lock Braking system

- Service Brakes or Foot oriented Brakes and

- Hand Brake System

1. Mechanical Brake System:

This mechanical braking system is the hand brake or the emergency brake, it generates friction between two surfaces as they rub against each other.

In this braking system, a particular force is applied to the pedal and it’s carried to the final drum by mechanical components such as a fulcrum, springs, and that are used as linkages to transmit force from one point to another, for slowing down the vehicle.

The slowing down of the speed or capacity of a brake depends on the surface friction as well the actuation force applied to it.

Advantages of Mechanical Braking System:

- Mechanical brakes are simpler and easy to be maintained.

- It is less expensive than a hydraulic brake system.

- It provides great uses for emergency and parking brakes.

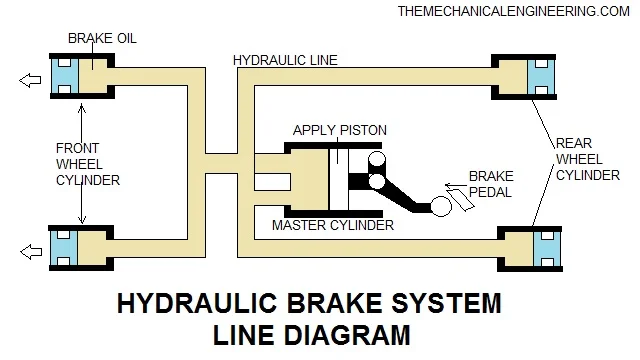

2. Hydraulic Braking System:

A magnetic flux is passed in a direction perpendicular to the rotating direction of the particular wheel, a rapid current flowing in a direction opposite to the rotation of the wheel creating an opposing force to the wheel rotation thus, gradually slowing down the wheel speed.

It transmits the brake system to the wheels of the brake through the pressure of fluids, converting the pressure into useful work for wheel brakes.

The Brake pedal relays the driver’s foot effort to the master cylinder piston, which compresses the brake fluid.

The fluid pressure is the same as it’s transmitted to the front disc-caliper pistons and the rear disc-caliper pistons. As per the process, a different mechanical parking brake must be included with at least two wheels.

This also allows the driver to be in control of the vehicle in the case of a failure with the Hydraulic Brake system.

Advantages of Hydraulic brake system

The Hydraulics offers the following advantages over the mechanical layout:

- It provides equal braking effort on all wheels.

- Relative brake effort is less to deliver the same output.

- It is fully compensated thus each brake receives a full share of pedal effort

- It is more efficient than mechanical.

- Suitable for all types of vehicles having independent suspension.

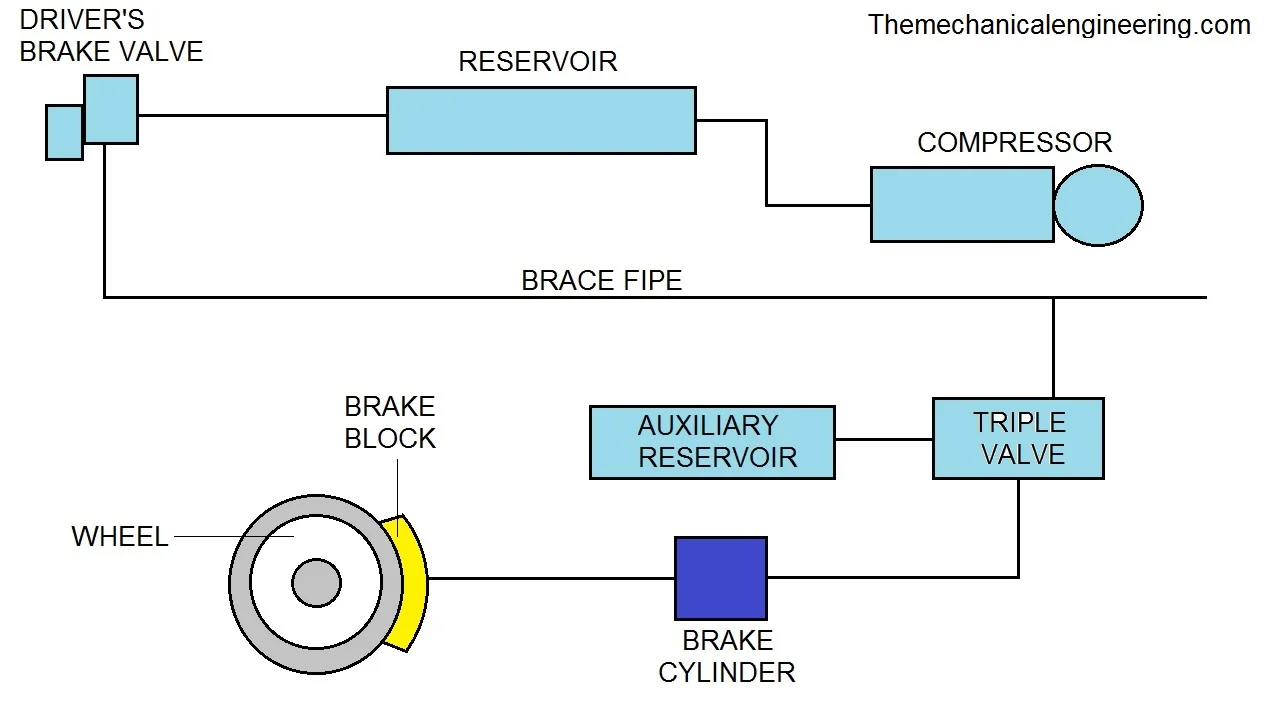

3. Pneumatic Braking System:

It maintains a higher level of pressure inside it, and the pressure in the line starts dropping the moment when the driver applies the brake causing a result in slowing down the vehicles trucks buses and trains use this type of braking system.

It operates on compressed air and helps in charging up the entire braking system to maintain optimum pressure.

The charged-up lines make sure the brakes are disengaged, the very moment the driver applies the force onto the pedal the air pressure drops.

Due to this sudden drop in pressure, the control reservoir, and gets disconnected causing the auxiliary cylinder to be connected to the brake cylinder.

Compressed air from the auxiliary cylinder gets to the brake cylinder causing it to be more engaged. This is how the pneumatic brake works.

Advantages of a pneumatic brake system:

- Pneumatic brake equipment is much more reliable than hydraulic brakes

- If there is a leakage in the pneumatic brake system, there is less wastage as compared to leakage in the hydraulic brake system.

- It is very powerful with a single pedal that can work the entire pneumatic brake equipment which makes everything easy to control and there are fewer chances of mistakes.

- Their systems are clean as the compressed air used in the operation can be directly dumped into the atmosphere.

Why the pneumatic system is not utilized in cars or light-duty vehicles?

Even though the air system got a lot of benefits over the hydraulic braking system, as well as its efficiency but it requires much more space to fit in the air braking system which has got several components in it.

Whereas another hydraulic system is lightweight and does not require much more space than an air braking system.

Also, the hydraulic system is much cheaper than the air braking system which does its job efficiently and effectively for the vehicle or cars.

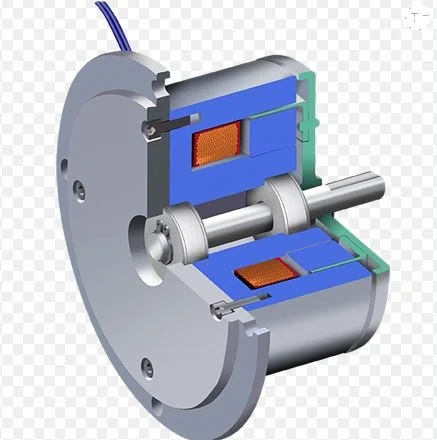

4. Electromagnetic Break System:

The electromagnetic system can be used in both modern and hybrid vehicles. The principles of electromagnetism are to achieve frictionless braking.

It increases the lifespan and reliability of the brakes also it’s backed by quick magnetic brakes so without the use of friction or any lubrication this technology is preferred in hybrids as they are moderate in size compared to normal braking. It is mostly used in trams and rails.

A magnetic flux is passed in a direction perpendicular to the direction of the rotating particular wheel, a rapid current flowing in a direction opposite to the rotation of the wheel creating an opposing force to the wheel rotation which hence reduces and slows down the speed.

Advantages of an electromagnetic field:

- The brake is faster and cheaper.

- There is no replaceable cost for brake shoes periodically.

- This breaking helps in increasing the capacity of the system.

- In this braking, a small amount of heat is generated wherein in mechanical braking an enormous amount of heat is generated.

- A part of the energy is delivered to the supply consequently the running cost is reduced.

5. Servo Braking System:

It is also known as vacuum-assisted braking. In this process, the pressure applied to the pedal by the driver is increased.

It uses the vacuum that is produced inside the petrol engines by the air intake system also it uses the power assistance to reduce the manpower effort.

Servo braking system boosters used with the hydraulic brake system increase the braking force applied on the surface, pushing the brake pedal to release the vacuum on the side of the booster the difference in the air pressure makes the diaphragm in slowing down.

Lets Have a look At the Advantages of Servo Braking:

- It is Simpler in design.

- It provides a greater level of safety because a loss in volume results in the breaking of the vehicle.

- More reliable in rail wagons.

- It’s simpler to control as it permits the automatic process of the brake down the entire length of the train by applying a decent force.

- It is more effective as its ability to get the partial release it’s something that the pneumatic brake could not do without adding additional equipment.

6. Electrical braking system:

It is mainly used in electric vehicles in which braking is produced using electric motors, and it’s the main power source in electric vehicles. It basically categorized into three types.

6.1 Plugging or Counter current Braking:

It is the simpler form of braking runs when gets connected to motor windings for the reverse direction of rotation at a particular time when the armature still rotates in the forward direction under control of the action of an external torque or due to inertia.

Plugging reconnects the power source with the motor, so it moves to drive in the opposite direction. It is generally obvious for the system to come at rest as it’s mostly required and then to accelerate in the reverse direction.

It is important to introduce a special device and to cut off the supply exactly at the time when the motor stops.

This method produces a greater braking torque. It’s beneficial to get a quick reversal or to get a more rapid stop in an event of the control.

It is mostly used in rolling mills, elevators, machine tools, etc. This method can be used in both direct current and alternating current and also in induction and synchronous motors.

6.2 Dynamic Braking system:

In this particular method, the motor power is cut from the supply and it operates as a generator carried by the kinetic energy of the rotating parts of the motor and its driven machines.

Thus, the kinetic energy gets converted into the electrical energy of the rotation.

Which is then dissipated and connected at the breaking instant. Using this method, the exact amount of energy required for the power supply to break the motor has been removed as compared to the plugging method.

And this is one of the advantages of dynamic Braking: It applies to direct current motors, synchronous motors, and induction motors.

6.3 Regenerative Braking:

In this method, the mechanical energy is converted into electrical energy. Some parts of energy are returned to the supply and the rest of the energy is lost as heat in the windings and bearings

of the electrical machines. It did not involve any switching method unless a change of speed is required at which it becomes more efficient.

Most of the wide electrical machines pass smoothly from motoring to operations generating, when getting overdriven by the load.

Necessities For Regenerative Brake System:

- Lesser Supply voltage.

- The motor is a little more excited.

- The motor is running at a higher speed than the no-load speed.

In all of this process, the retarding torque is produced and the armature current is reversed, decreasing the speed of the motor until the armature back emf becomes the same as a voltage source.

Regenerative braking does not stop the motor. It is only efficient for handling braking and hauling loads, they also vehicle increased the motor due to the work of lowering load or in the motor of an electric locomotive moving downgrade.

Advantages of Electric Braking:

- It’s more efficient than the mechanical braking system which needs costly and frequent replacement but no such replacement is required in electric braking hence it’s cheaper and works efficiently.

- By using of electric braking, the speed capacity of the system increases way higher with haulage of heavy loads.

- It helps in saving energy, as a small number of energy returns to supply offering a considerable saving in the operating cost.

- Metal dust is produced in mechanical braking, but no such dust is produced in the electric placement of the mechanical brakes may result in harsh effects in the discomfort to occupants. On the other side electric braking is way safer, smoother, and without shock.

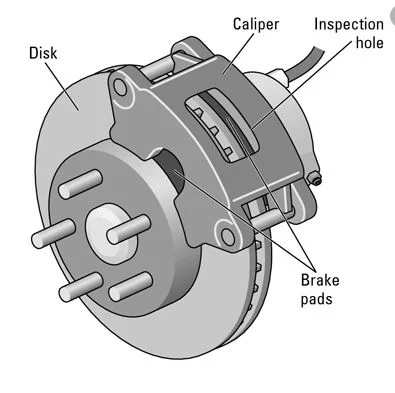

7. Disc Brake System:

Brake Fluid is compressed by a piston inside the master cylinder located at the base of the vehicle hood beside the engine, thus creating a huge amount of hydraulic pressure, also producing a large amount of force just by pressing the pedal down.

The pressure gets passed via the brake fluid and then to brake horses that connect a linkage with the brake assembled at each wheel.

The conversion of wheel pressure takes place with the hydraulic force being converted to the mechanical force causing the brake friction to push against the disc, and the drum helps to decrease the speed and stop it completely.

7.1 The floating caliper:

It is the most common type used with one or two pistons, when the brakes are applied, the inner brake pad gets rested against the disc while at the exact time, the caliper body shifts closer to the router.

This process forces the outer brake pad against the router.

7.2 The fixed caliper:

Its piston is mounted on each side of the router. The caliper does not bulge out, it is rigidly fastened to the spindle. When applying brakes, the caliper piston shifts, pressing the brake pads against the disc.

Advantages of Disc brake System

- It produces more force-stopping power.

- More efficient to apply for a shorter stopping distance.

- Provides a self-cleaning facility.

- This is more durable and lighter.

8. Drum Braking System:

It is the brake type in which a drum which is mainly used for the brake shoes along with its real mechanism is attached to the hub of the wheel in such a way the inner parts remain constant and the outer part of the drum rotates with the wheel.

When brakes are applied, the mechanical linkages cause the brake shoes to expand a little due to which the outward friction surface of the brake shoes gets in frictional contact with the rotating drum part which helps in stopping or de-accelerating the wheels.

Advantages Of Drum Brake System

- It generates less heat since most of the stopping force is generated by the front brakes of the vehicle.

- It produces or emits less particulate matter than disc brakes.

- Its frictional contact area is at the circumference hence it provides more braking force than an equal-diameter disc brake.

- It got a low level of maintenance to improve corrosion resistance compared to the disc.

- It is less expensive and reliable.

9. Emergency Brake System:

They are also known as parking brakes, it acts as secondary and independent braking System for all service brakes.

There are several kinds of emergency brakes (a level between the driver placed, a third pedal, a handle beside the steering column, etc.)

They are all sourced by cables that apply the pressure mechanically to the wheels, generally maintain the vehicle stationary when parked, and are used in emergency situations if the stationary brakes are not at work.

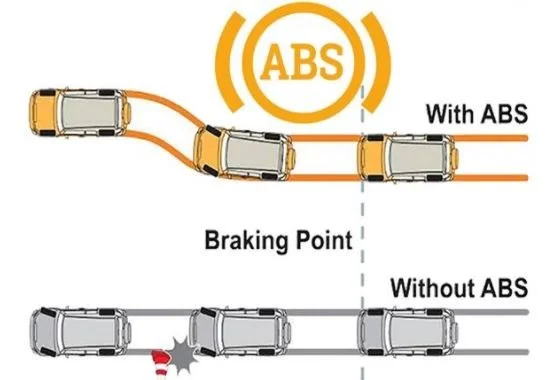

10. Anti-lock Braking system:

Most modern vehicles are introduced anti-lock Braking systems. They are installed for good reasons for several advantages mostly having to do with driver and passenger safety.

For beginners, anti-lock brakes allow drivers to maintain control of their vehicles in all types of road conditions.

It provides rushing stopping at the exact point where the driver wants, without using these brake roads with slippery conditions can turn out a bit risky.

One of its great advantages is that its system parts work together, for instance, ABS controls wheel activity with the sensor placed on both wheels. The sensor is controlled by the brake force ensuring the wheel’s speed runs in tandem.

11. Service Brakes or Foot oriented Braking System:

It is an automobile’s primary braking system operated by one’s foot and mechanically separated from the partner brake for emergency braking. Its braking system can be compared to both drum brakes and disc brakes.

Its functions are mainly hydraulic, thus using hydraulic pressure to activate the braking system. It basically uses a bias with most of the braking force to be applied onto the front brakes. It means a vehicle to be under control under heavy braking events.

Vehicles with high rear brake bias, cause vehicles to lose control and slide out under heavy braking conditions. Too much front brake bias also causes the same event to happen.

12. Hand Brake System:

A hand Brake system is also known as a parking brake or emergency brake. It helps to keep the vehicle motionless while parking, it is used to perform in emergency situations when the main hydraulic brakes fail.

This consists of a cable connected with two wheels brakes and then connected to a pulling mechanism.

In most vehicles, the parking brake is found to be operated only on the rear wheels, which reduces the traction while braking.

This mechanism consists of a hand-operated and a steering column or foot-operated pedal located with some other pedals. In the event of failure, the parking brake engages to prevent the wheels from locking up and reduces speed.